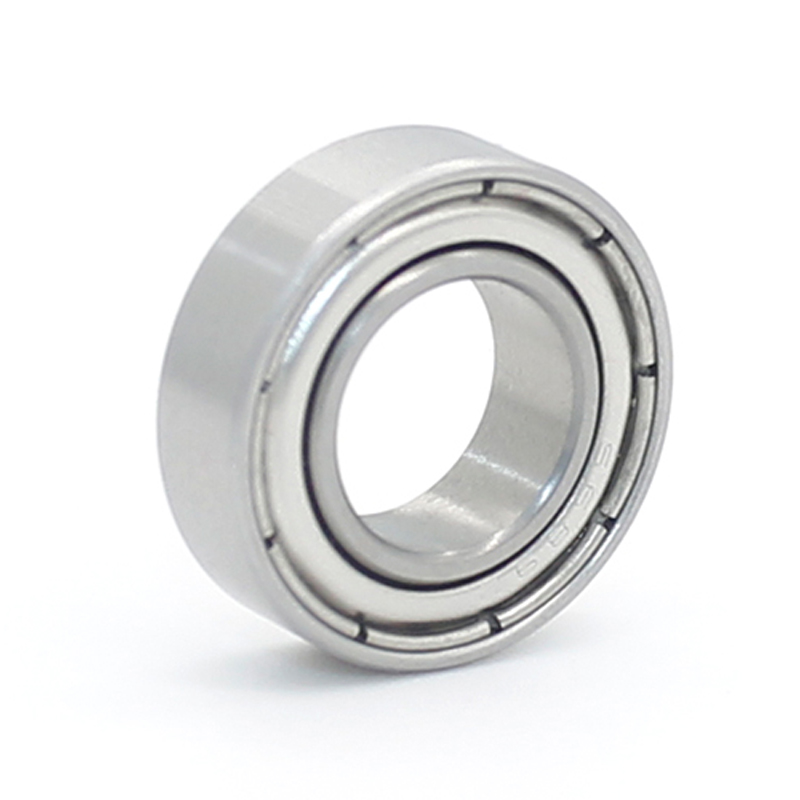

Hair dryer bearing 694ZZ 694-2RS

Part Number: 694ZZ,694-2RS

Measurement System: Metric

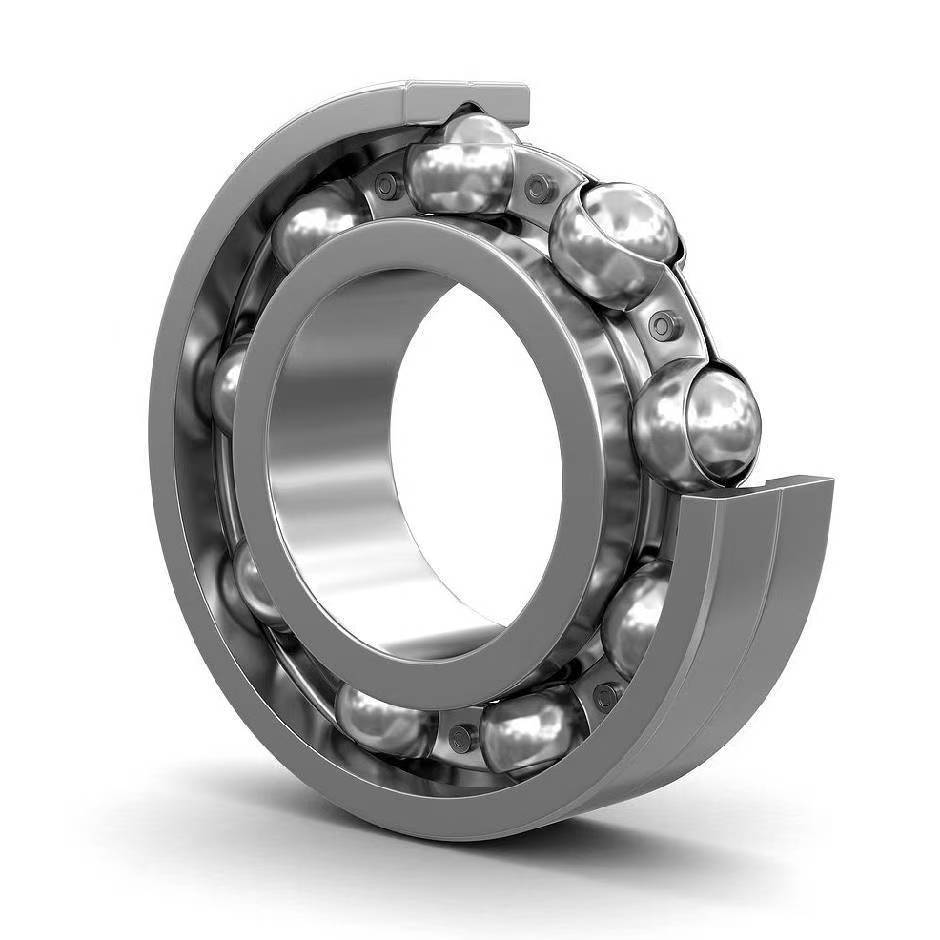

Bearing Type: Ball Type

Load Direction: Radial

Structure: Single Row

Seal Type: Shielded

Inner Diameter: 4 mm

Inner Diameter Tolerance: -0.008 mm to 0

Outer Diameter: 11 mm

Outer Diameter Tolerance: -0.008 mm to 0

Width: 4 mm

Width Tolerance: -0.12 mm to 0

Ring Material: Chrome Steel

Ball Material: Chrome Steel

Cage Material: 300 Series Stainless Steel

Lubrication: Required

Shaft Mounting Type: Press Fit

Temperature Range: -30° to 120 ℃

ABEC Grade: ABEC 1 | ISO P0

Radial Clearance Class: C3 Normal

RoHS: Compliant

REACH: Compliant

Dynamic Radial Load: 183 lbf

Static Radial Load: 63 lbf

Design Features of the 694 2rs Bearing

The 694 2rs bearing is specifically designed to provide reliable and efficient performance in confined spaces, making it an excellent choice for industrial applications where space is limited. The inner diameter of the 694 2rs is 4 mm, and the outer diameter is 11 mm. The material of the balls in the 694 2rs is chrome steel, and its sealing type is sealed. This bearing features high-speed performance, low friction, and low noise levels, delivering optimal performance. It complies with industry standards for precision and durability, and is suitable for a variety of applications in different industries that require compact space solutions.

Applications of the 694 2rs Bearing

The 694 2rs bearing is widely used in industries that demand high precision and compact design, including but not limited to cryogenic coolers, lung assist devices, clocks and watches, and instrumentation. It is also utilized in fuel control, monitoring systems, and gyroscopes. Due to its small size and reliable performance, this bearing is popular in applications where space is limited but high precision is required.

Maintenance and Troubleshooting Tips for the 694 2rs Bearing

Regular maintenance is crucial to ensure the optimal functionality and long-term use of the 694 2rs bearing. It is recommended to frequently check the bearing for signs of contamination, wear, or damage. It can be cleaned using a non-corrosive solvent and then thoroughly dried before lubrication. If there are any signs of excessive wear or damage, the bearing should be replaced immediately. In addition, make sure to troubleshoot any issues in the application to ensure that the bearing is used within its intended parameters

For more product information, please contact our engineer:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com

Website: www.blhbearing.com

Bai Li Hong Bearing Co., Ltd.

Address: No. 7, Liyuan Road, Zhangmu Town, Dongguan City, Guangdong Province, China