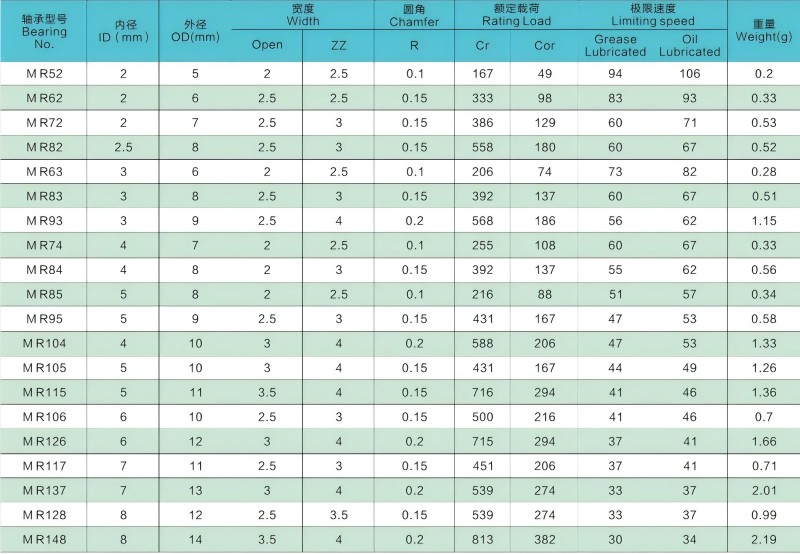

MR DEEP GROOVE BALL BEARING SERIES;

MR52 MR62 MR72 MR84 MR93 MR74 MR84 MR85 MR95 MR104 MR105 MR115 MR106 MR126 MR117 MR137 MR128 MR148

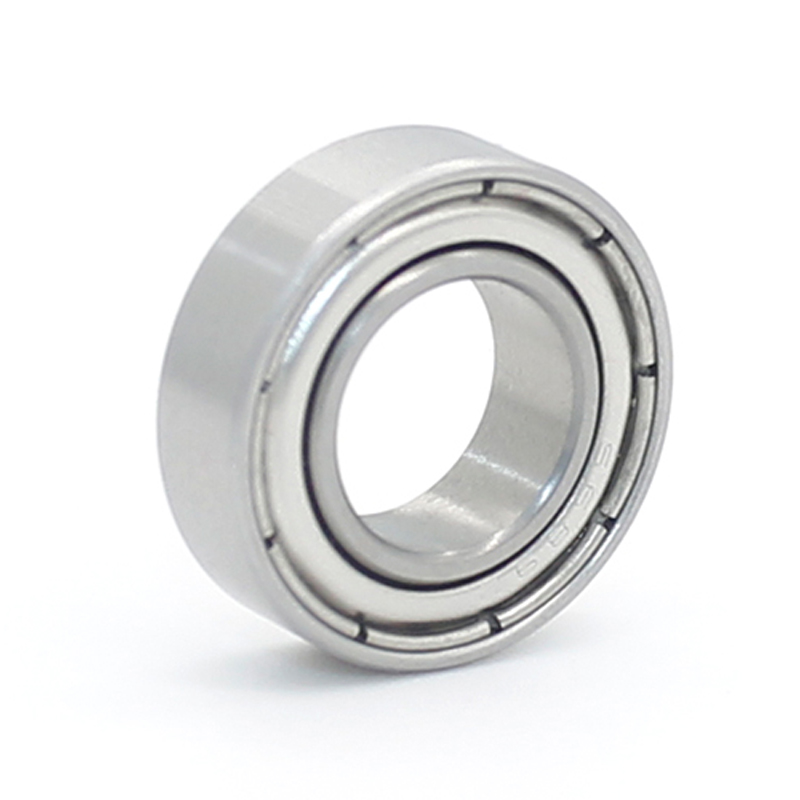

Seal type:Open/ZZ/RS

Material: GCr15, SUS420, SUS440, SUS304, SUS316, PP, POM, PEEK, Ceramic.

Precision:P0,P2,P4,P5,P6

Trade terms:FCA, FOB, CIF, DDP(USA)

Material and precision: Generally, high-quality stainless steel materials such as 440C are used, which have good corrosion resistance and high strength. In the manufacturing process, extremely high precision is required. The roundness and cylindricity of the inner and outer rings, as well as the dimensional accuracy and surface quality of the balls are strictly controlled to reduce unbalanced forces and vibrations during high-speed rotation.

Internal structure optimization: To meet the requirements of high-speed rotation, the internal structure of the bearing has been optimized. For example, appropriately increasing the diameter and quantity of the balls to improve the carrying capacity and reduce collisions between the balls; optimizing the design of the cage, using lightweight and high-strength materials and a reasonable structure to reduce the resistance and wear of the cage during high-speed rotation.

Application scenarios: Mainly used in equipment that requires high-speed rotation, such as high-speed motors, spindles of precision machine tools, auxiliary transmission systems of aerospace engines, high-speed rotating parts in medical devices, etc. In these devices, the high-speed performance of the bearing can ensure the efficient operation and precise control of the equipment.

Can be used for various small motors, such as micro motor bearings, DC motor bearings, etc. Its high precision and low friction characteristics help the efficient operation of the motor, reduce energy consumption and noise, and improve the service life and performance of the motor bearings. It is commonly found in the installation of motor bearings in some small power tools, household appliances and other equipment.If you want to know more about product technical knowledge, you can contact us by email.

I am a Chinese bearing factory capable of solving all technical problems related to bearing transmission. Welcome to contact me at:

jackengineer@blhbearing.com.