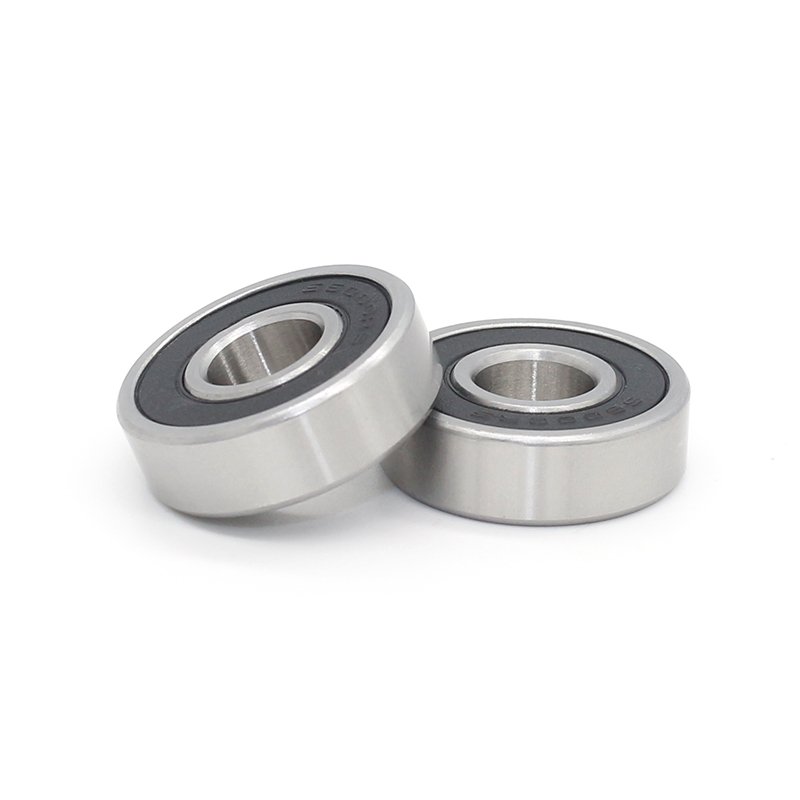

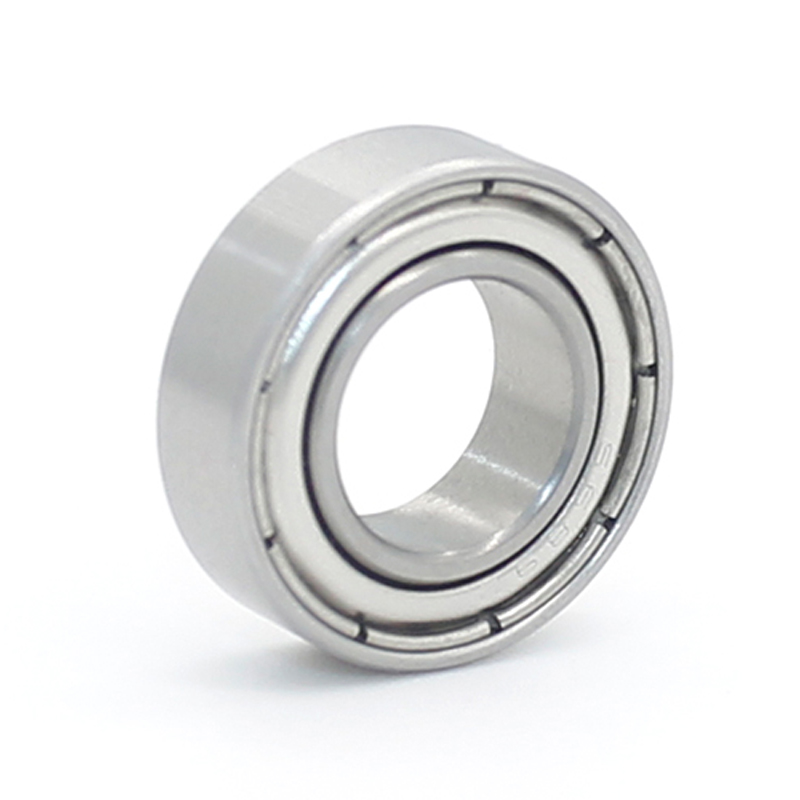

Deep groove ball bearing 6000RS for painting production line

In coating production line equipment, the 6000RS bearing plays an important role in ensuring stable rotation of the shaft, reducing friction and energy loss, and improving the operating efficiency and reliability of the equipment, as follows:

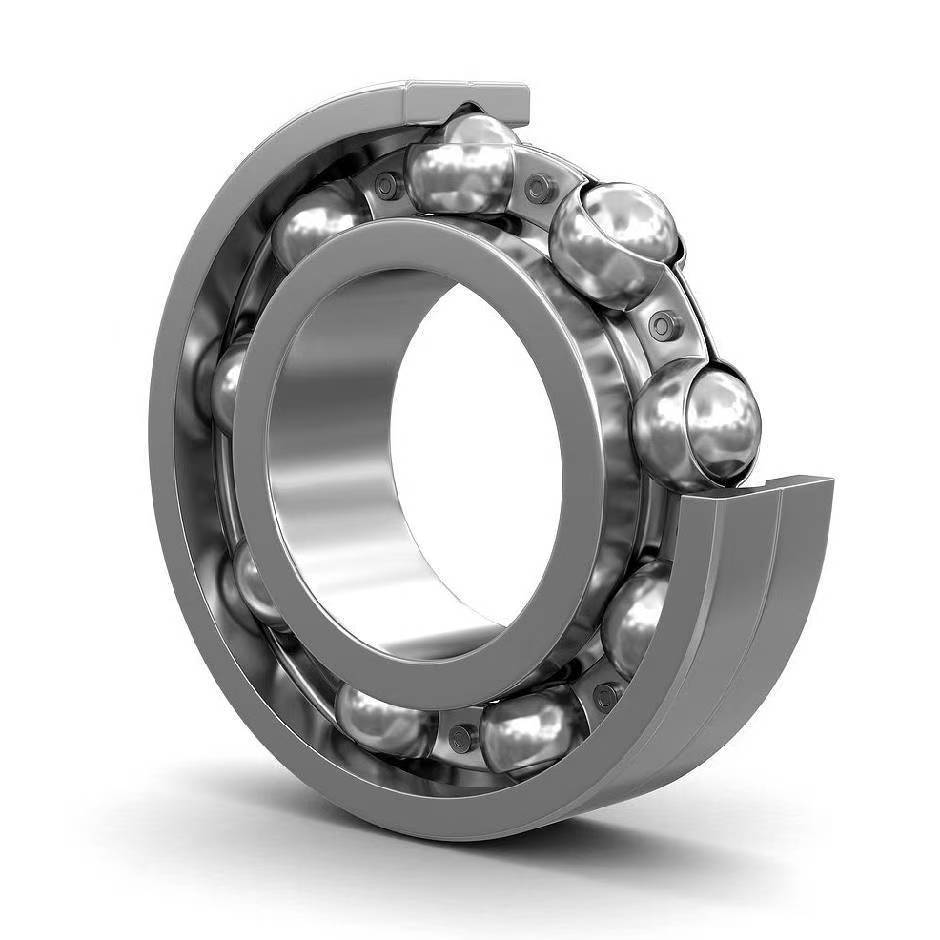

Ensuring stable rotation of the shaft: Many components of the coating production line, such as the sprocket shaft of the suspended conveyor chain, the rotating shaft of the drying oven, and the pump shaft of the main circulation pump for electrophoretic paint, need to perform rotational motion during operation. The 6000RS bearing has high-precision raceways and steel balls, which can provide precise support for these rotating shafts and control the radial and axial runout of the shaft within a very small range, thereby ensuring stable rotation of the shaft, ensuring smooth operation of the equipment, and avoiding problems such as component wear, unstable workpiece transportation, and decline in coating quality caused by shaft shaking or vibration.

Reducing friction and energy loss: The rolling elements of the 6000RS bearing are in point or line contact with the raceway, and the friction coefficient is much lower than that of sliding bearings. When the shaft rotates, the rolling elements roll in the raceway, greatly reducing the frictional resistance. At the same time, the sealing design of the bearing (such as the single-sided seal represented by RS) can effectively prevent grease leakage and maintain a good lubrication state, further reducing friction. This reduces the energy required to drive the shaft rotation during the operation of the equipment, reduces energy loss, improves energy utilization efficiency, and helps reduce production costs.

Improving the operating efficiency and reliability of the equipment: Since the 6000RS bearing can ensure stable rotation of the shaft and reduce friction, the various components of the equipment can operate more smoothly, reducing the number of equipment shutdowns and maintenance due to bearing failures. In addition, this bearing has high load-carrying capacity and good wear resistance, can withstand various complex loads in the coating production line, including radial loads and a certain amount of axial loads, can adapt to different working conditions, and prolongs the service life of the equipment, thereby improving the operating efficiency and reliability of the entire coating production line, ensuring the continuity and stability of production, and helping to improve product quality and production efficiency

For more product information, please contact our engineer:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com

Website: www.blhbearing.com

Bai Li Hong Bearing Co., Ltd.

Address: No. 7, Liyuan Road, Zhangmu Town, Dongguan City, Guangdong Province, China