I am a Chinese bearing factory capable of solving all technical problems related to bearing transmission. Welcome to contact me at:

jackengineer@blhbearing.com.

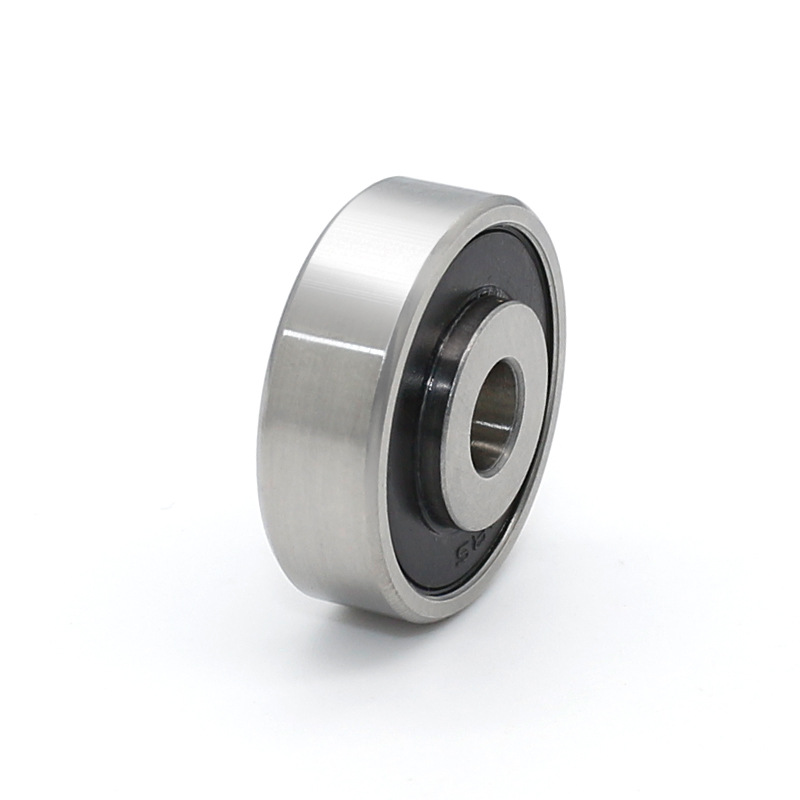

Bearing S6000ZZ specially for ovens

The core advantages of the high-temperature bearing sliding wheel S6000ZZ in the environment of 300℃ inside the oven's inner furnace:

Material Advantages

SUS304 Stainless Steel:

High Temperature Resistance: The long-term stable operating temperature can reach up to 300℃ (the conventional design limit is 800℃, but in practical applications, the performance at 300℃ is more reliable).

Corrosion Resistance: Compared with ordinary steel, 304 stainless steel is less likely to rust in a humid or mildly corrosive environment inside the oven.

Lightweight: The stainless steel material is lighter than traditional cast iron, making it suitable for equipment that needs to be moved.

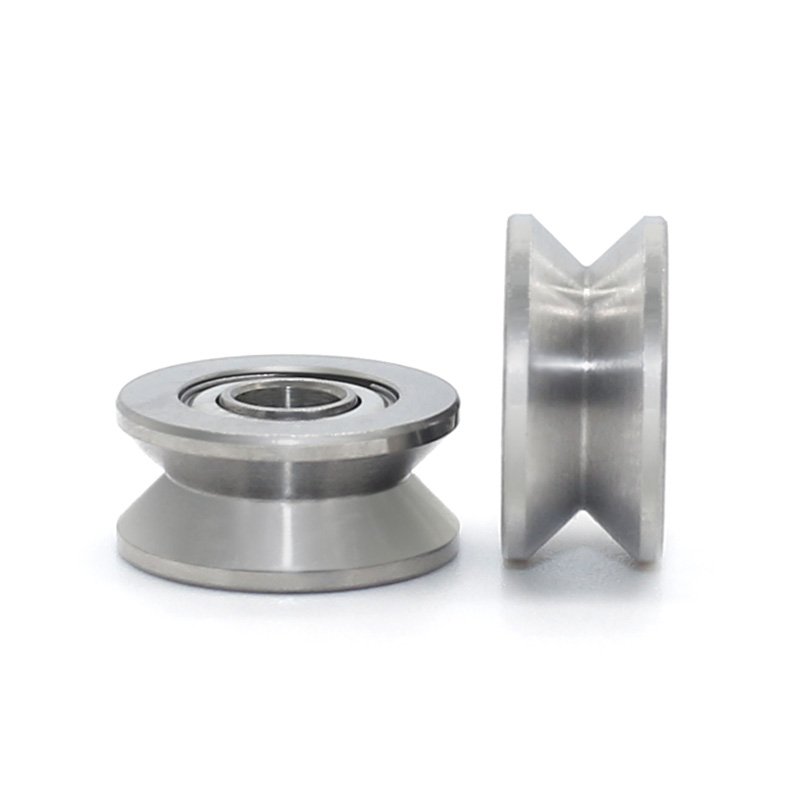

Bearing Design Features

Deep Groove Ball Structure (S6000ZZ):

High Rotational Speed Adaptability: It is suitable for the medium to high-speed operation requirements of conveyor belts or moving parts inside the oven.

Low Friction Resistance: The small contact area between the rolling elements and the raceway reduces energy consumption and heat generation.

Sealing Protection (ZZ Type):

The double-sided metal dust cover design effectively prevents dust, grease, or steam inside the oven from entering the interior of the bearing, extending its service life.

Adaptability to High Temperature Environments

Pre-filled High Temperature Grease:

Some customized models are equipped with high-temperature resistant grease (such as perfluoropolyether grease), which can still maintain lubrication performance at 300℃, avoiding jams or wear caused by lubrication failure.

Clearance Optimization:

Radial clearances are pre-set (such as C3/C4) to compensate for material expansion under high temperatures and prevent the bearing from seizing up.

Advantages in Application Scenarios

Oven-specific Design:

Optimized for the continuously high-temperature and low-humidity environment inside the oven, it is more durable than ordinary wheels.

Maintenance-free:

The sealing structure reduces the need for daily maintenance, making it suitable for production lines or commercial ovens that operate continuously for long periods.

Our factory specializes in producing various types of deep groove ball bearings; ball bearings; double row ball bearings; pulley bearings; sealed waterproof bearings; steel ball bearings; small bearings; non-standard bearings; custom bearings, rubber-coated bearings, and rubber-coated pulleys. Materials include: GCr15, AISI420(3CR13), AISI440C(9Cr18Mo), AISI304(0Cr18Ni9), AISI316(0Cr17Ni12Mo2), AISI630(0Cr17Ni4Cu4Nb). Complete in various models. Welcome to consult! The characteristics of our products are high temperature resistance, corrosion resistance, high speed, and low noise.

For more product information, please contact our engineer:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com

Website: www.blhbearing.com

Bai Li Hong Bearing Co., Ltd.

Address: No. 7, Liyuan Road, Zhangmu Town, Dongguan City, Guangdong Province, China