6204RS plastic bearing for semiconductor photovoltaic conveying wheels

High-Quality Plastic Bearings for Semiconductor Photovoltaic Conveying Equipment

In the context of the rapid development of semiconductor photovoltaic technology, the importance of reliable and high-performance components cannot be overemphasized. Nowadays, Chinese factories are at the forefront of manufacturing plastic bearings, which are revolutionizing the field of semiconductor photovoltaic conveying equipment. One outstanding product among them is the 6204RS plastic bearing, whose unique features make it an ideal choice for this industry.

The 6204RS Plastic Bearing: A Masterpiece of Engineering

The 6204RS plastic bearing reflects the precision and innovation demonstrated by Chinese manufacturers. The "RS" marking indicates the presence of a single-sided rubber seal. In the semiconductor photovoltaic environment, this seal plays a crucial role as it can effectively keep out dust, debris, and other contaminants. In the cleanroom environment, which is common in semiconductor manufacturing, even the tiniest particle can cause serious disruptions to the production process. The 6204RS plastic bearing, with its robust seal, ensures that the conveying system remains free from contaminants and safeguards the integrity of the photovoltaic products being processed.

The design of the 6204RS bearing also enables smooth and efficient rotation. This is of vital importance for the precise movement of photovoltaic materials along the conveyor belts. In semiconductor manufacturing, precision is key, and any deviation in the movement of materials may lead to defects in the final products. The 6204RS plastic bearing reduces friction through its optimized design, allowing the conveying system to operate with minimal energy consumption while maintaining high-speed and accurate movement.

Polyphenylsulfone (PPSU) Insulated and High-Temperature Resistant Bearings: Meeting Industry Demands

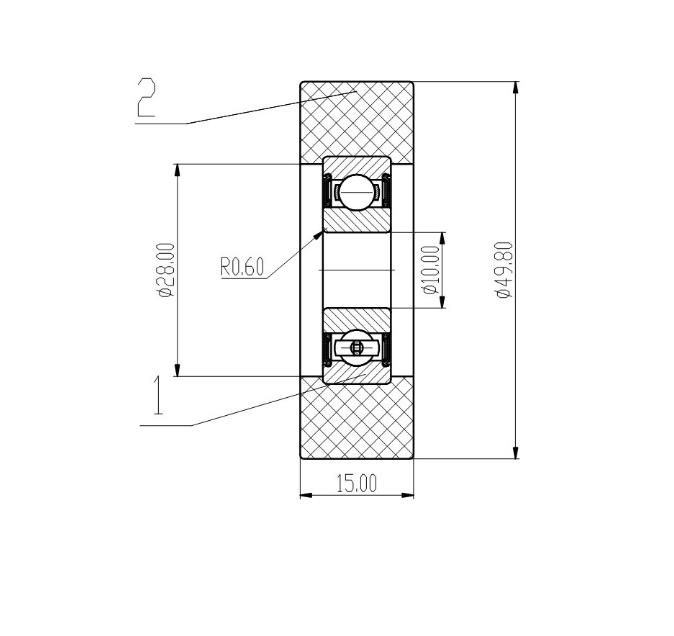

For semiconductor photovoltaic conveying equipment, the use of polyphenylsulfone (PPSU) insulated and high-temperature resistant bearings, especially those with dimensions of 105015mm, offers numerous advantages. PPSU is a high-performance thermoplastic with excellent electrical insulation properties. In the semiconductor industry, where electrical interference can be a major concern, these bearings provide a reliable solution. They can prevent electric current from flowing through the conveying system and protect sensitive electronic components from potential damage.

Moreover, the high-temperature resistance of PPSU bearings is transformative. Semiconductor manufacturing processes often involve high-temperature environments, especially during the wafer processing and soldering stages. The 105015mm PPSU bearings can withstand these elevated temperatures without deforming or losing their mechanical properties. This ensures the continuous and reliable operation of the conveying equipment even under the most challenging conditions.

Applications in Semiconductor Photovoltaic Conveying Equipment

In semiconductor photovoltaic manufacturing plants, these plastic bearings are applied in various conveying systems. They play an indispensable role in the movement of photovoltaic wafers from one processing station to another. Whether it is the initial stages of wafer cleaning and inspection or the final assembly and packaging processes, the 6204RS plastic bearings and the PPSU insulated and high-temperature resistant bearings ensure smooth and accurate material handling.

The use of these bearings also contributes to the overall durability and lifespan of the conveying equipment. By reducing friction and wear, they minimize the need for frequent maintenance and replacement. This not only saves time and cost but also improves the production efficiency of semiconductor manufacturing plants.

Why Choose Bearings Made in China

Chinese factories have invested heavily in research and development to produce these advanced plastic bearings. They combine state-of-the-art manufacturing technologies with high-quality raw materials to ensure that each bearing meets the strictest industry standards. In addition, Chinese manufacturers offer competitive prices, making these top-notch bearings accessible to semiconductor photovoltaic enterprises around the world.

In conclusion, when it comes to equipping semiconductor photovoltaic conveying equipment with reliable and high-performance plastic bearings, the 6204RS plastic bearing and the 105015mm PPSU insulated and high-temperature resistant bearing produced by Chinese factories are the top choices. Their unique features, durability, and cost-effectiveness make them an essential part of any semiconductor manufacturing plant looking to optimize its production process

For more product information and solutions, please contact our engineers:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com