Keywords for IP67 waterproof bearing S606ZZ shower room track pulley

Solution for Rubber-Coated Roller of Bearing S606ZZ Shower Room Track Pulley

I. Product Overview

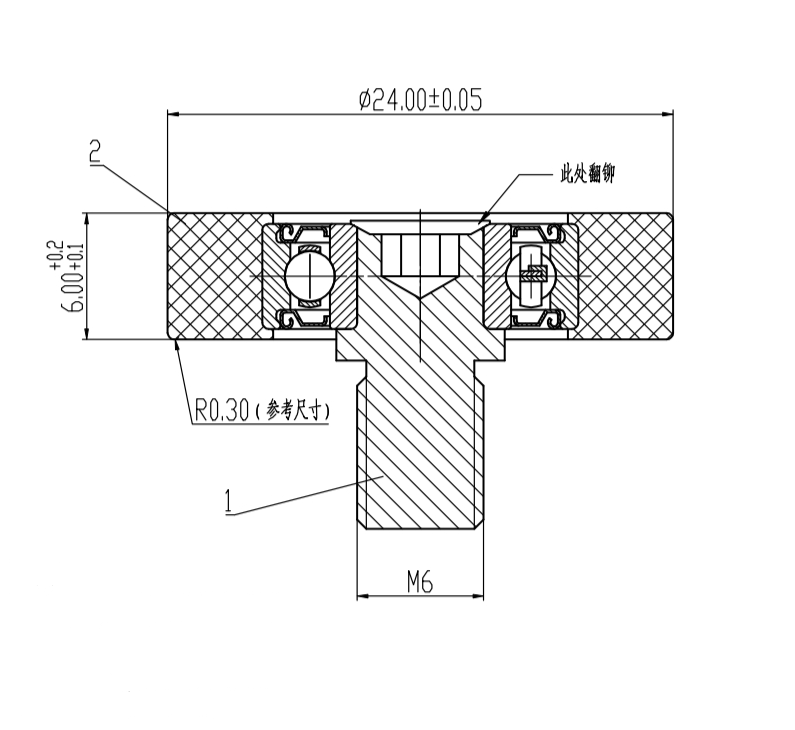

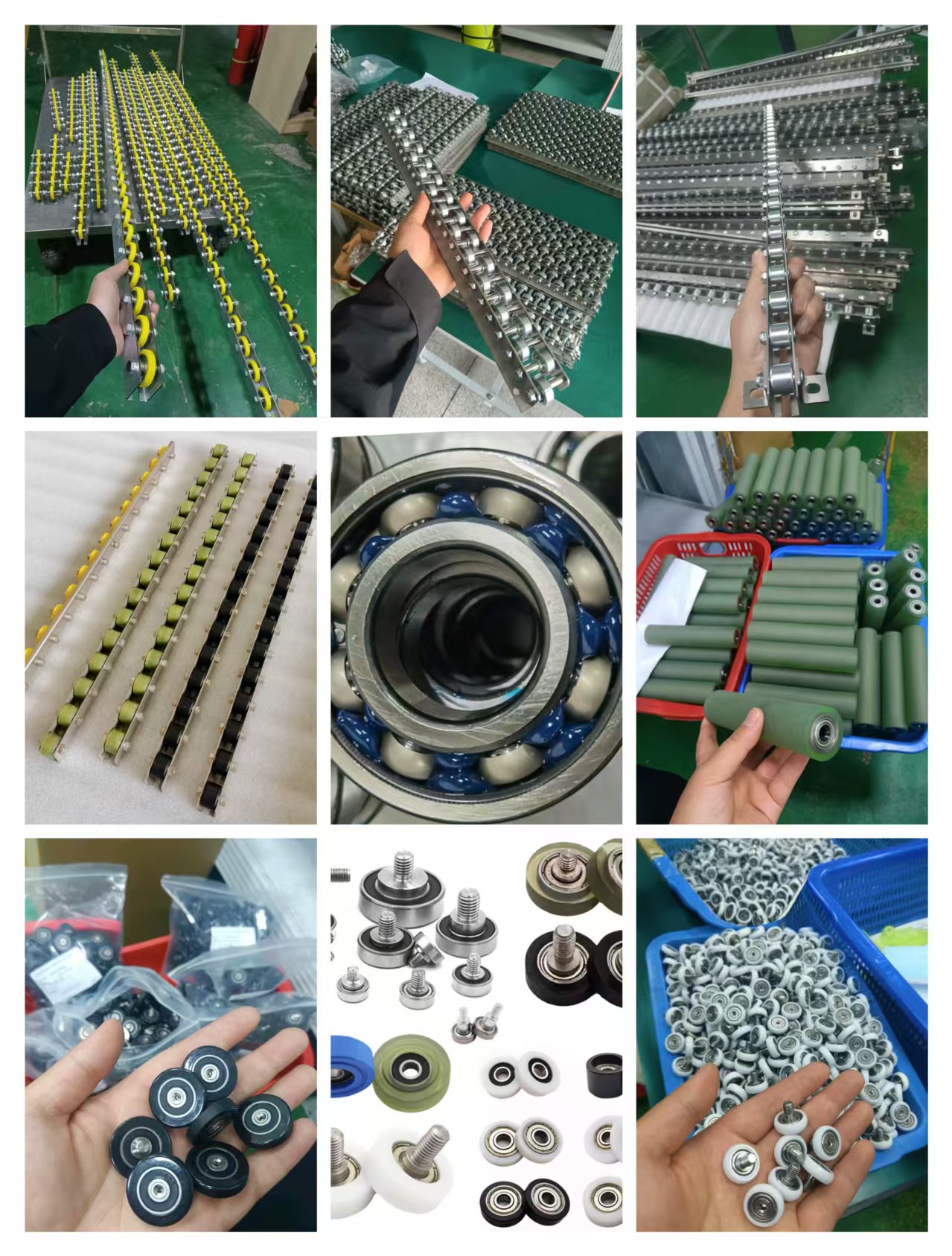

The bearing S606ZZ shower room track pulley adopts the process of embedding rubber coating in a deep groove ball bearing, which is suitable for a micro transmission system with an inner diameter of 6mm. With an outer diameter of 17mm and a thickness of 6mm, the outer layer is wrapped with polyurethane (PU) or silicone material. It has the characteristics of silent sliding, water resistance, corrosion resistance, and high load-bearing capacity. It is specifically designed for track systems such as shower room glass doors and partitions, and can bear a load of 50-80kg, ensuring smooth opening and closing and long-term stable operation.

II. Core Advantages

Material and Performance

Rubber Coating Layer:

Polyurethane (PU): With a Shore A hardness of 85-95, it has good elasticity, wear resistance, and impact resistance, and strong hydrolysis resistance (suitable for humid environments).

Silicone: With a Shore A hardness of 70-80, it has high flexibility and resistance to high and low temperatures (-40°C to 150°C), making it suitable for steam shower rooms.

Bearing Steel Core: Made of AISI 52100 bearing steel with a chromium plating treatment on the surface, the anti-rust grade reaches C5-M (salt spray test ≥ 100 hours).

Structural Design

Double Sealing Protection:

The built-in metal dust cover (ZZ) isolates dust, and the extended design of the edge of the rubber coating layer forms a secondary waterproof barrier.

Some models can be optionally equipped with a rubber sealing ring (2RS), reaching the IP65 waterproof grade.

Low Friction Coefficient: μ≈0.08 (PU). Combined with the H-shaped wheel groove design, it reduces track jams, and the noise during door opening and closing is ≤ 45 decibels.

Adaptability

Installation Method: It supports hook type, screw type (M5-M6), snap type, etc., and is suitable for mainstream shower room track profiles (such as aluminum alloy T-shaped grooves).

Customized Groove Type: The depth (3-5mm) and radian of the wheel groove can be adjusted to be suitable for different track widths (12-20mm).

III. Typical Application Scenarios

Shower Room Glass Door Pulley

The PU rubber-coated S606ZZ pulley (1766mm) is used in the upper hanging rail system, with a load-bearing capacity of 60kg, resistance to scale erosion, and a service life of more than 5 years.

Bathroom Partition Sliding Door

The silicone rubber-coated model (with a temperature resistance of up to 150°C) is suitable for steam shower rooms, and the anti-aging performance is increased by 30%.

Customized Bathroom Furniture

The S606ZZ pulley with a screw rod (M5 thread) is used for the mobile storage rack, which is silent, smooth, and has a stable load-bearing capacity.

IV. OEM/ODM Customization Services

Parameter Customization

Rubber Coating Hardness: Shore A 70-95 is optional to meet different damping requirements (such as buffer type or fast sliding type).

Size Adjustment: The outer diameter can be expanded to 20mm, and the thickness can be increased to 8mm to be suitable for non-standard track systems.

Surface Treatment

Texture of the Rubber Coating Layer: Anti-slip patterns and flow guide groove designs can be customized to reduce water accumulation residues.

Bearing Coating: PVD coating (such as TiN) is optional, which can increase the hardness to HV2000 and be resistant to scratching.

Logo and Packaging

Brand logos are laser engraved, and neutral packaging or customized color boxes (such as waterproof packaging) are supported.

V. Quality and Service Assurance

Inspection Standards

The bearing steel core complies with the ISO 492 standard, and the rubber coating layer passes the ASTM D412 tensile test (elongation rate ≥ 400%).

Cyclic Life Test: Simulate 100,000 times of opening and closing without failure (with a load of 60kg).

Service Support

Technical Response: Provide track system adaptation solutions and feedback installation guidance within 24 hours.

Conclusion

With the characteristics of water resistance, silence, and high load-bearing capacity, the S606ZZ rubber-coated roller has become an ideal choice for shower room track systems. The OEM/ODM services can flexibly adapt to customer needs, empower the entire chain from material selection to structural design, and help bathroom equipment manufacturers improve their product competitiveness.

For more product information, please contact our engineer:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com

Website: www.blhbearing.com

Bai Li Hong Bearing Co., Ltd.

Address: No. 7, Liyuan Road, Zhangmu Town, Dongguan City, Guangdong Province, China