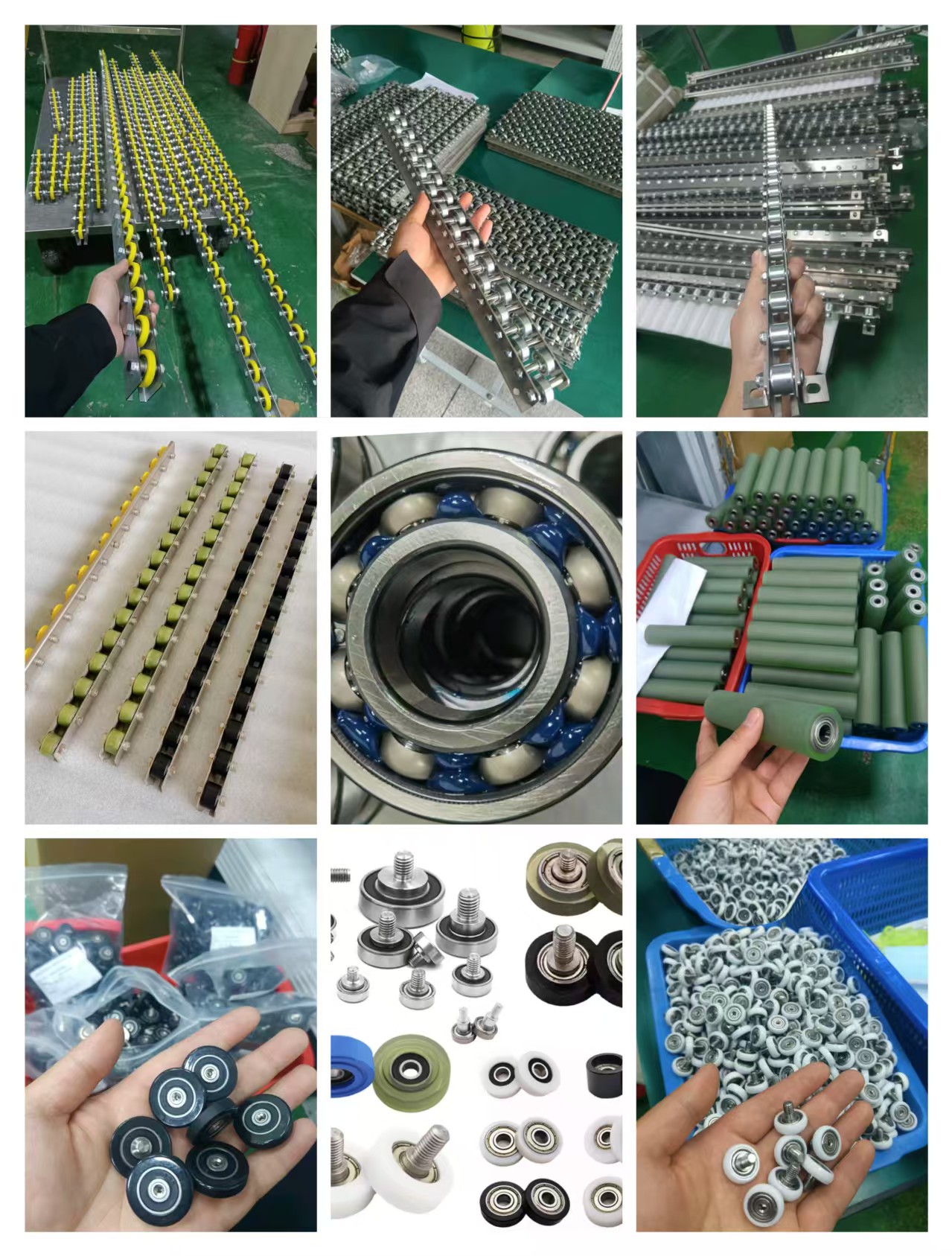

OEM/ODM economical rubber-coated bearing products

I. Product Overview

The economical rubber-coated bearing 625ZZ is a lightweight transmission component specifically designed for customers with small and medium batch orders. It adopts the injection molding process with an embedded deep groove ball bearing, and is suitable for micro transmission systems with an inner diameter of 5mm. The outer diameter of the product ranges from 16 to 24mm, and the thickness is between 5 and 10mm. According to requirements, rubber coating materials such as POM, polyurethane, and nylon can be selected. It has the characteristics of silence, wear resistance, and corrosion resistance, and is widely used in scenarios such as 3D printer rails, door and window pulleys, and engraving machine transmissions.

II. Core Advantages

Diversified Material Adaptation

POM Rubber Coating: It has high hardness (Shore D80) and a low friction coefficient (μ≈0.12), making it suitable for high-frequency sliding scenarios, such as the guide wheels of 3D printing platforms.

Polyurethane Rubber Coating: It has good elasticity (Shore A90) and fatigue resistance, and is resistant to the erosion of wood chips and dust. It is suitable for the pulleys of panel saws in woodworking machinery.

Nylon Rubber Coating: With a lightweight design (density of 1.15g/cm³), it has a remarkable silent effect and is suitable for light-load environments such as drawer slides and curtain tracks.

Modular Structure Design

Multiple Installation Forms: It supports installation forms with screw rods (M4-M6), U-shaped grooves, and double knurling anti-slip designs, and is suitable for different equipment interfaces.

Customized Groove Types: H-shaped, V-shaped, and arc-shaped wheel grooves are provided to optimize the transmission efficiency of belts/ropes and reduce the risk of slipping.

Economical Performance Balance

Cost Control: The injection molding process reduces material loss, and the cost of a single set is 40%-60% lower than that of international brands, making it suitable for customers who are sensitive to the budget.

Life Assurance: The bearing steel core cooperates with the rubber coating layer for buffering, and the load capacity reaches 20kg (radial), and the service life is more than twice that of pure metal bearings.

III. OEM/ODM Customization Services

Full-process Development Support

Parameter Customization: The hardness of the rubber coating (Shore A50-A95), the temperature resistance range (-20°C to 100°C), and the dimensional accuracy (±0.1mm) can be adjusted.

Structure Optimization: For high-speed rotation requirements (≤3000rpm), the dynamic balance design is strengthened, or a sealing lip (2RS) is added to improve the waterproof and dustproof performance.

Logo Customization: Brand logos and model parameters are laser engraved, and neutral packaging or customized color boxes are supported.

Large-scale Production Capacity

Rapid Prototyping: The mold development can be completed within 7-10 days, and the samples can pass the salt spray test (no rust within 48 hours) and the radial load test (150N@100,000 times).

IV. Typical Application Scenarios

3D Printing Equipment

The arc-shaped POM rubber-coated bearing 625ZZ (5*24*10mm) is used in the gantry guide system to reduce the vibration of the printing platform and improve the accuracy of layer lines.

Smart Home

The nylon rubber-coated bearing with a U-shaped groove (5*22*7mm) is suitable for the damping slides of drawers, operating silently and being resistant to humid environments.

Woodworking Machinery

The polyurethane rubber-coated bearing (5*25*9mm) is used for the roller of plate conveying, which is resistant to the wear of wood chips and extends the maintenance cycle to more than 2000 hours.

V. Quality and Service Assurance

Inspection Standards

The bearing steel core complies with the GB/T 18254-2016 standard, the rubber coating layer has passed the RoHS certification, and some models have passed the IP54 waterproof test.

Service Support

Technical Response: Installation guidance and failure analysis reports are provided, and customer complaints are responded to within 24 hours.

Conclusion

The economical rubber-coated bearing 625ZZ, with its material innovation, modular design, and cost advantages, has become an ideal choice for the upgrade of the transmission systems of small and medium-sized manufacturing enterprises. The OEM/ODM services can flexibly match the needs of customers, empower the whole chain from design to delivery, and help enterprises improve their product competitiveness.

For more product information, please contact our engineer:

Jack / Engineer Manager.

Wechat / Tel:0008613095650338

E-mail: jackengineer@blhbearing.com

Website: www.blhbearing.com

Bai Li Hong Bearing Co., Ltd.

Address: No. 7, Liyuan Road, Zhangmu Town, Dongguan City, Guangdong Province, China