Plastic Bearing689

Plastic bearings 689 dedicated to intelligent sweeping robots usually have the following characteristics:

Good wear resistance

During the working process of the bearings of intelligent sweeping robots, they need to move and turn frequently. Wear-resistant deep groove ball plastic bearings 689 will continuously generate friction with other components. Therefore, they need to have good wear resistance. Usually, wear-resistant engineering plastics are used to produce the inner and outer rings of bearings, such as polyoxymethylene (POM). POM material has high hardness and toughness. Its surface hardness can reach about Rockwell hardness M90. It can withstand the friction generated by sweeping robots when driving on the ground, reduce bearing wear and prolong service life.

Low noise characteristics

Since sweeping robots work indoors, the environment has high requirements for noise. Deep groove ball plastic bearings 689 pay attention to reducing noise in design and material selection. On the one hand, plastic itself has certain shock absorption and sound absorption properties. Compared with metal deep groove ball bearings, it can reduce vibration and noise transmission during operation. On the other hand, the internal structure design of the bearing is also crucial. For example, precisely processed balls and raceways fit tightly and smoothly, minimizing the friction and collision sounds when the balls roll in the raceway, ensuring that the sweeping robot will not generate excessive noise that interferes with users' lives during the cleaning process.

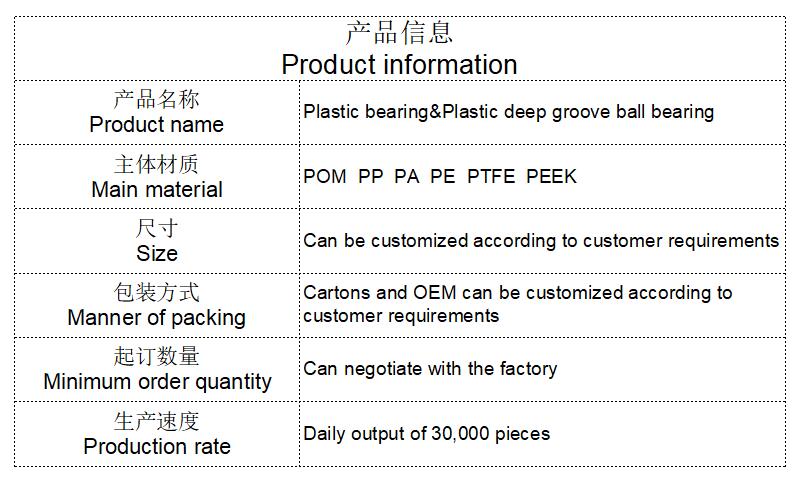

Plastic bearings have the following characteristics: good self-lubrication, good corrosion resistance, light weight, low noise, and good insulation. They have a wide range of uses. We have 20 years of production experience. Various materials and sizes can be customized for production. Welcome to contact us.

I am a Chinese bearing factory capable of solving all technical problems related to bearing transmission. Welcome to contact me at:

jackengineer@blhbearing.com.