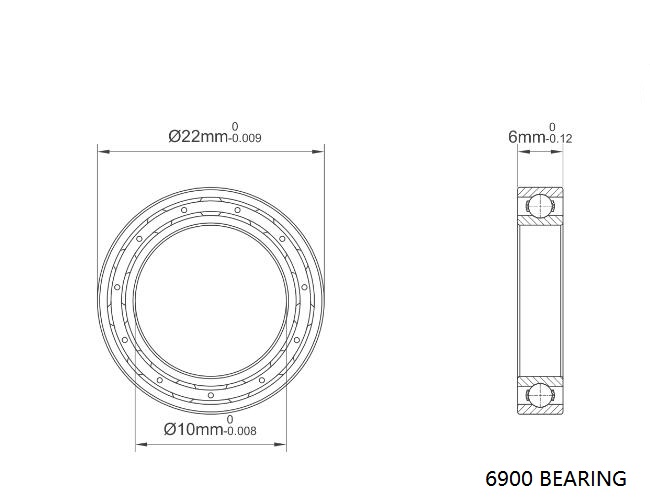

Plastic bearings 6900 dedicated for underwater robots usually have the following characteristics:

Good corrosion resistance: The underwater environment usually has strong corrosiveness. Seawater, fresh water, etc. may cause corrosion to metal bearings. While plastic bearing 6900 is generally made of corrosion-resistant engineering plastics such as polyetheretherketone (PEEK), polyphenylene sulfide (PPS), polytetrafluoroethylene (PTFE), etc. These materials can resist the erosion of chemical substances such as acids, alkalis, and salts, and can work in underwater for a long time without rusting and corrosion, thus ensuring the performance and service life of plastic deep groove ball bearings.

Lightweight: The density of BLH plastic deep groove ball bearings is much lower than that of metal deep groove ball bearings. The weight of deep groove ball plastic bearing 6900 is only 1/5 to 1/3 of that of metal deep groove ball bearings. This is very important for underwater robots. Reducing the weight of bearings can reduce the overall energy consumption of underwater robots, improve their energy utilization efficiency, increase endurance and operation time. At the same time, it also helps to achieve the lightweight design of underwater robots, making their movement in water more flexible and agile.

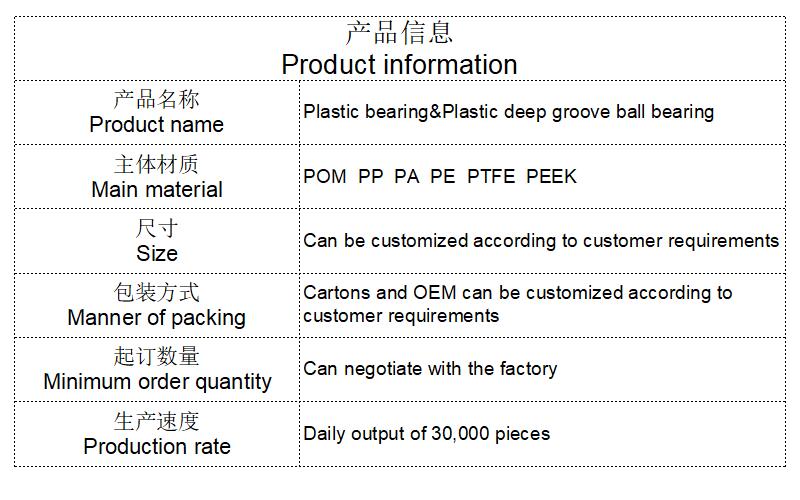

Plastic bearings have the following characteristics: good self lubrication, good corrosion resistance, light weight, low noise, and good insulation. They have a wide range of uses. We have 20 years of production experience. Various materials and sizes can be customized for production. Welcome to contact us.

I am a Chinese bearing factory capable of solving all technical problems related to bearing transmission. Welcome to contact me at:

jackengineer@blhbearing.com.